Process Solutions International has released an enhanced line of MAX2000 Material Handling Equipment, focusing on safety and efficiency. The launch includes maintenance-friendly mud agitators, cost-saving shear hoppers, and safety-integrated screw conveyors for the global oil and gas market.

Houston, TX, United States, 9th Dec 2025 – Process Solutions International (PSI), a recognized leader in the manufacturing of drilling fluid management systems, has officially launched an upgraded suite of products within its MAX2000 series. This strategic expansion focuses on their heavy-duty Material Handling Equipment, designed to deliver superior operational continuity and safety for oil and gas operators across the Permian Basin, the GCC region, and global offshore markets.

With over thirty years of industry experience, Process Solutions International continues to bridge the gap between American manufacturing excellence and the rugged demands of the energy sector. The enhanced product line addresses the critical need for “cradle-to-grave” solids control, ensuring efficient transport, mixing, and disposal of drilling fluids and cuttings.

Revolutionizing Solids Control Efficiency

In the high-pressure environment of modern drilling, the management of drilling fluids (“mud”) is a cornerstone of operational success. Inefficient equipment can lead to costly non-productive time (NPT), hazardous working conditions, and inconsistent fluid properties. PSI’s latest engineering advancements are directly targeted at these challenges, offering robust solutions that reduce maintenance intervals and improve chemical integration.

The updated equipment portfolio focuses on three core pillars: maximizing fluid consistency, ensuring operator safety, and reducing chemical costs.

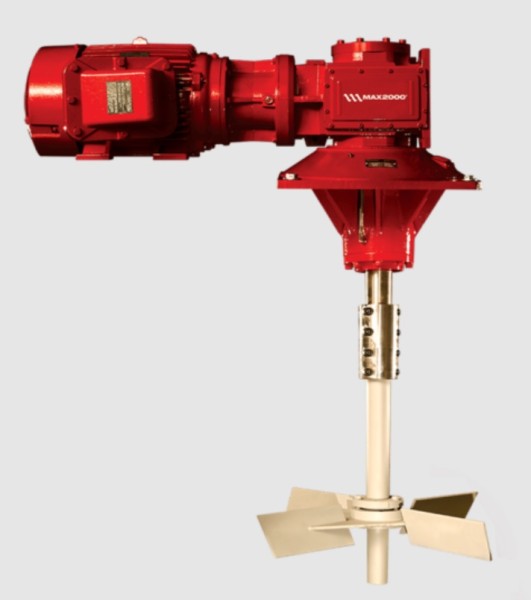

MAX2000 Mud Agitators: The End of In-Tank Maintenance

A standout in the new lineup is the MAX2000 Mud Agitator, specifically engineered to eliminate one of the most dangerous maintenance tasks on a rig: confined space entry. Traditional agitator designs often require crews to enter mud tanks to service lower bearings, posing significant safety risks.

PSI has re-engineered this process with a focus on longevity and accessibility:

- Top-Side Serviceability: The unique design allows for the lower bearing to be maintained entirely from the top of the tank, removing the need for tank entry and drastically improving safety compliance.

- Helical Bevel Efficiency: Utilizing high-efficiency helical bevel gearing, these units achieve up to 98% efficiency. This ensures maximum torque transfer to keep solids suspended, even in high-viscosity fluids, preventing settling and tank bottoms buildup.

- Redundant Sealing: The system employs four distinct layers of protection to isolate the lower bearing from abrasive drilling fluids, ensuring a longer lifespan and reduced replacement costs.

High Shear Hoppers: Reducing Operational Costs

Chemical additives represent a massive line item in any drilling budget. Inefficient mixing leads to waste and “fish eyes”—unhydrated clumps of polymer that can damage downstream equipment. PSI’s High Shear Hoppers feature a specialized 6” Mixing Eductor and a durable Urethane Nozzle that generate intense turbulence within the fluid stream.

This “Venturi” effect guarantees rapid, uniform hydration of additives. Field applications have demonstrated that this material handling equipment can reduce Bentonite and polymer consumption by up to 50%, providing operators with substantial cost savings while maintaining optimal rheology.

Safety-First Conveyance Systems

The transport of drill cuttings is a process fraught with mechanical hazards. PSI has standardized safety features on their Screw Conveyors that are typically considered aftermarket upgrades by other manufacturers.

These modular systems are custom-built to fit specific rig footprints but adhere to a universal “Safety First” standard:

- Immediate Shutdown: Full-length, side-mounted emergency pull cables and remote stop switches allow any crew member to instantly halt operations from any point along the conveyor.

- Audio-Visual Warnings: Integrated strobe lights and high-decibel alarm horns provide clear indications of equipment status, preventing startup accidents.

- Operator Protection: Heavy-duty troughs and secure top grates ensure that personnel are protected from moving augers while still allowing for the efficient transport of semi-solid waste.

Global Availability and Rapid Support

“We build our equipment to survive the harshest environments, from the Texas heat to the Middle Eastern desert,” says Kye Keliehor of Process Solutions International. “But durability must be matched with availability. By stocking critical units and spares in our global hubs, we ensure that our clients never have to wait for the tools they need to keep the bit turning.”

To support this promise, PSI maintains extensive inventory of pumps and material handling equipment at its headquarters in Houston and its strategic international offices in Dubai and Al Khobar, Saudi Arabia. This global footprint allows for rapid deployment of OEM parts and service technicians to major drilling hubs worldwide.

About Process Solutions International

Headquartered in Houston, Texas, with additional facilities in Dubai and Saudi Arabia, Process Solutions International is a premier manufacturer of industrial pumps, solids control systems, and fluid management solutions. Since 1991, PSI has delivered robust, American-made equipment designed to meet the extreme challenges of the oil and gas industry.

Website: www.psimax2000.com

Media Contact

Organization: Process Solutions International

Contact Person: Kye Keliehor

Website: https://psimax2000.com/

Email: Send Email

Contact Number: +12818934774

Address:7519 Prairie Oak Dr

City: Houston

State: TX

Country:United States

Release id:38720

The post Process Solutions International Optimizes Oilfield Safety with Enhanced Material Handling Equipment Line appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Insure Information journalist was involved in the writing and production of this article.